- Home

- Our Business

- Products by Industry

- Next-Generation Automotive Industry

Products by Industry

#05

Next-Generation Automotive Industry

Industrial structures and trends in the automotive industry change rapidly on a daily basis. We provide the latest technologies, equipment, and services that flexibly respond to such changes in the market while leveraging our long-established business relationships, trust, and networks with customers and suppliers.

Our Role in the Next-Generation Automotive Industry

We have been focusing on responding to the increasing trend of electrification in the industry since early on, and over the years we have accumulated a wealth of experience and achievements ranging from the development of equipment for motors, batteries, and inverters to the development of mass production facilities, all in cooperation with our customers and suppliers. We provide solutions tailored to our customers' needs by leveraging our collective capabilities and networks, both in Japan and abroad.

Main Products

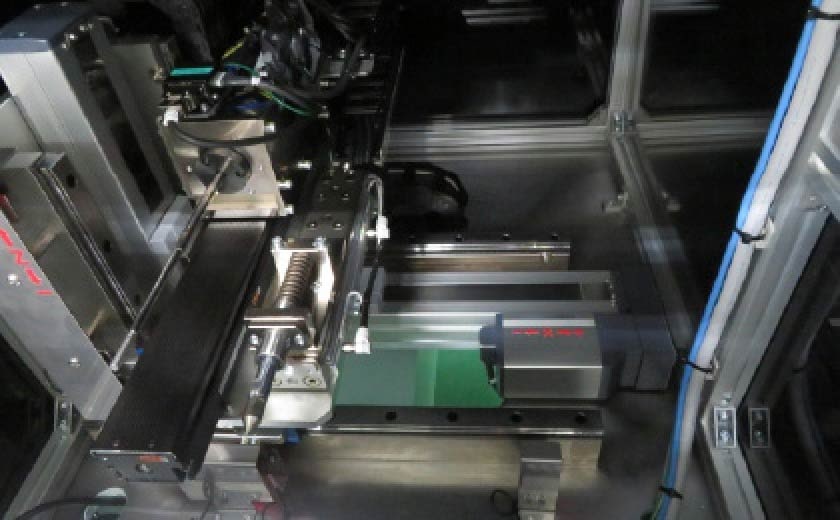

Automatic Assembly & Processing Lines

We provide customized machinery, equipment, and services in collaboration with various equipment manufacturers based on our customers’ needs. In recent years, manufacturing processes have become more complex, and the number of large-scale projects has been increasing.

We also focus on handling servo presses and nut runners, which are in increasing demand in the assembly process, and offer optimal equipment for all machining processes in general, including turning, cutting, drilling, and grinding various automotive parts (motor/inverter parts, brake parts, engine parts, transmission parts, etc.). In addition, we not only sell stand-alone equipment, but also offer total coordination for the entire processing line, including transfer, measuring, and cleaning equipment.

Various Conveyance Systems

We offer conveyance systems according to a wide range of required specifications, including everything from the supply of various parts to inter-process transportation, finished product work stock, and shipping.

In recent years, more companies have been adopting new construction methods and technologies, such as unmanned transport using AGVs (automated guided vehicles) utilizing IoT, as well as picking up workpieces randomly placed in containers using image processing. The adoption of automated transportation systems has greatly contributed to streamlining labor and promoting unmanned manufacturing processes.

Proposals of Various Types of Automatic Inspection & Measuring Systems

We propose various systems such as CMMs (coordinate measuring machines) that can handle micron-level precision inspections, X-ray CT scans for inspecting the inside of parts, and inspection and measurement systems for parts machining processes. Utilizing our track record in the inspection and measurement processes for engine and transmission parts, in recent years, we have accumulated a wealth of experience in vehicle electrification components, as well as automated inspections in non-automotive sectors. Mitsubishi Corporation Technos helps customers streamline their workforce and achieve consistent quality by introducing automatic inspection and measuring systems.

Highly Precise Self-Aligning Steady Rest Technology

About Arobotech Systems, Inc.

About Arobotech Systems, Inc.

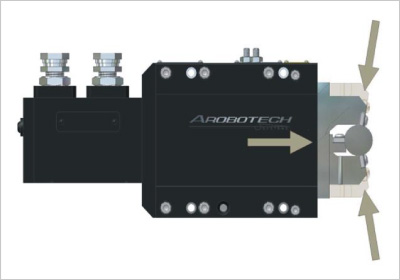

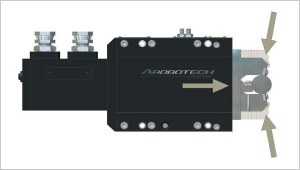

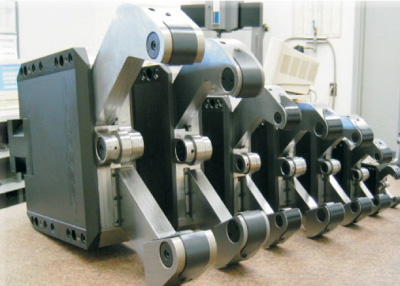

Arobotech Systems, Inc. (Arobotech Systems) was established in Michigan, U.S.A., in 1983 for the purpose of manufacturing precision steady rest solutions for turning and grinding long materials. With its many years of experience and advanced technology as a specialized manufacturer of steady rest solutions, Arobotech Systems provides its highly precise, rigid, and high-quality steady rest technology (product name: AUTO REST®) to customers around the world. Steady rest solutions manufactured by Arobotech Systems, which have a unique mechanism called a sliding wedge that does not require any internal pins, cams, or bearings, etc., have obtained various patents in many countries around the globe.

*Sliding wedge mechanism: A drive mechanism that fundamentally uses large, flat bearing surfaces rather than other high wear points.

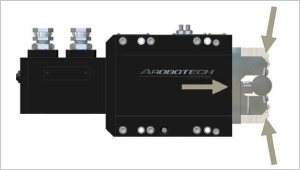

The unique three-point gripping arm system allows the workpiece to stay centered at all times.

In addition to Arobotech System’s extensive product lineup, the company designs products to meet customer specifications. The devices are installed one by one by skilled workers and must pass rigorous testing involving precision grinding with 0.001mm repeatability before being shipped.

The sliding wedge mechanism ensures rigidity, making the unit extremely robust, allowing it to be used for many years even under harsh machining conditions. It is also very easy to install and adjust, which saves a lot of time.

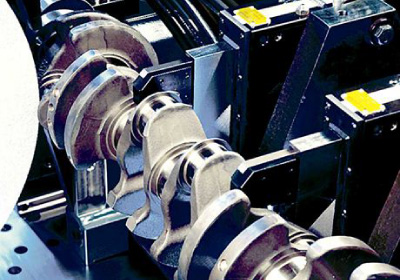

Arobotech System’s steady rest solutions are highly regarded by customers who demand high quality in automotive parts such as camshafts and crankshafts, as well as ball screws and long tools (drills, broaches, etc.). The company also offers repair and inspection services after delivery.

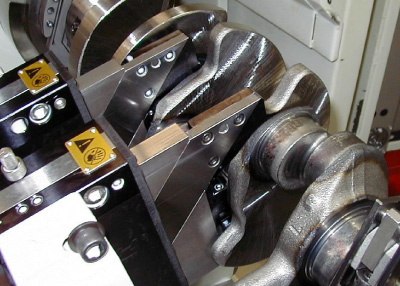

Crankshaft grinding

Outstanding Features

1. Three-point gripping arm

- Three-point gripping arm with excellent steady-rest performance always keeps the workpiece centered

2. High precision

- Achieves high accuracy using a simple mechanism (repeatable centering accuracy within 1μm)

Ideal for machining workpieces that require high accuracy - Self-centering function that keeps the workpiece on center throughout the grind cycle

3. High rigidity

- Simple slide wedge mechanism with no internal cams, hinges, pins, etc.

- Pads that come in contact with the workpiece are made of PCD (polycrystalline diamond) or carbide

- All mechanisms are controlled by a single hydraulic cylinder and the workpiece is held by a three-point gripping arm

4. User friendly

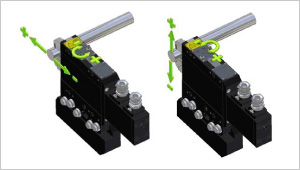

- Dedicated adjustment screw allows for fine horizontal and vertical adjustments and reduces time spent making adjustments

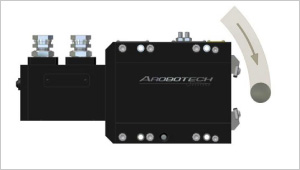

- Arm retract function for easy workpiece attachment and removal

- Sliding wedge mechanism for easy maintenance

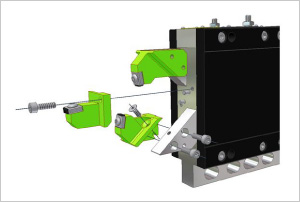

- Clamp range can be adjusted by replacing the nest (pad)

5. Designed & produced according to requests

- In addition to the standard lineup, the device can be designed and produced according to customers’ requests.

- Compact, low-profile design that allows users to flexibly change cylinder position, etc.

- Freely adjustable grip diameter that can be changed according to the size of the workpiece

- Examples of design and production

Low-profile arm (to be used with a sizing instrument)

Change in contact angle (for crank pin grinding)

Special pads for heavy and long cutting processes

6. Increased productivity

- Highly precise steady rest technology that meets strict tolerance requirements

- Less time spent making anti-sway adjustments

- More grinding workpieces produced per hour

- Longer service life for grinding wheels

The three-point gripping arm maintains a steady centerline regardless of the size of the workpiece’s outside diameter.

Centering grinding function

Fine horizontal and vertical adjustment function

Arm retract function for easy workpiece attachment and removal

Dedicated nests that allow for flexible changes in diameter

Use Cases

Arobotech Systems has been selling its steady state solutions for about 20 years and has already delivered more than 1,000 units in Japan. The company helps to improve quality and cycle time by improving roundness and making it easier to adjust grinding size at many of its customers' production sites. Here are some examples of how Arobotech System’s solutions have been used in the past.

Crankshaft Grinding

The company also offers a low-profile arm model for use with sizing instruments. The contact angle of the three-point gripping arm can also be changed for use in pin grinding.

Camshaft Grinding

The three-point gripping arm always grips the center of the journal. Can be used for both journal grinding and lobe grinding.

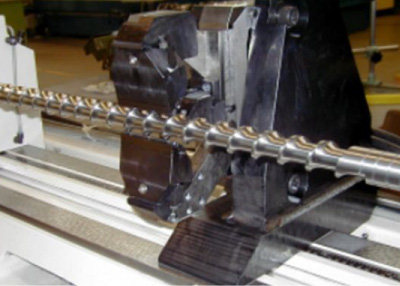

Injection Screw Grinding

The pad can be designed to match the screw pitch. Can be used for both groove grinding and outer diameter grinding.

Small-Diameter Workpiece Grinding

Can hold workpieces as small as 1 mm.

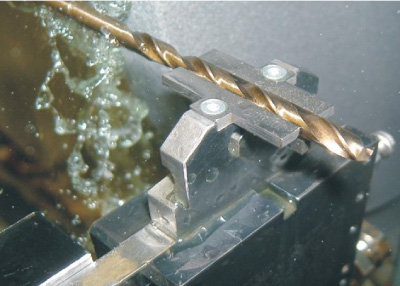

Tool Grinding

Can be used for both outer diameter and groove grinding.

The fine adjustment function makes it easy to adjust for changes in workpiece diameter.

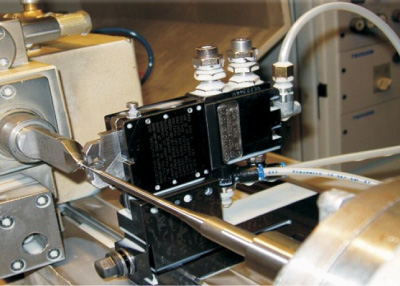

Steady Rest Solutions for Turning

The company also offers a diverse lineup of steady rest solutions for turning.

For inquiries, please contact:

Manufacturing Equipment & Machinery Dept., Nagoya Branch

TEL:+81-52-565-2641

FAX:+81-52-565-1989

Arobotech Systems, Inc. Website

Visitors can download the company’s catalogs and view reference videos.

- #01 Die/Mold & Sheet-Metal Industries

- #02 Aviation & Defense/Space Industries

- #03 Construction Machinery Industry

- #04 Energy Industry

- #05 Next-Generation Automotive Industry

- #06 Foods, Oils/Fats & Soap Industry

- #07 Semiconductor Industry

- #08 DX- & GX-Related

- #09 Additive Manufacturing (3D Printer) Industry